Custom Roll Forming

OMCO manufactures highly engineered, custom roll formed shapes for many applications across a wide range of industries. Custom built components for truck bodies, trailer frames, material handling, solar panel frames and supports, conveyors, escalators, and many more industries are manufactured cost effectively using roll forming technology.

OMCO has six manufacturing operations strategically located across the United States. Locations include Ohio, Indiana, Alabama and Arizona. Together, these facilities total over 700,000 square feet, operate over 50 roll forming lines, and utilize more than 50 stamping presses.

What sets us apart from other roll formers is our skill in integrating superior roll forming practices with other valuable manufacturing services to deliver the highest quality, most cost-effective solution to our customers.

US Manufacturer of Highly Engineered, Custom Roll Formed Shapes

Roll Forming Plus = Value Added Operations

The integration of additional manufacturing operations directly into the roll forming process, or implemented as a secondary operation, is utilized in the manufacture of nearly every roll formed part OMCO produces. Whether our customer needs to add holes, notches, bends, hardware, or some other feature into their part, OMCO can find a cost-effective method to satisfy that requirement.

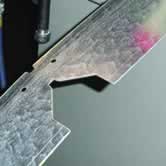

Closed Welded Shapes

3 Robust Hi-Frequency Weld Lines

Capable of producing custom tubes with up to 0.25″ thick steel

- In-line eddy current weld quality monitoring

- In-line eddy current weld quality monitoring

- Zinc re-metalizing system

- Zinc re-metalizing system

Go beyond the basic square, round or rectangular tubes. Highly engineered closed welded shapes can be tooled up to be produced in one of OMCO’s three roll forming weld lines. All three of these lines are located in the U.S.A. and incorporates high-frequency welding, a robust pre-punch press, an inline eddy current monitor, and re-metalizing capability.

Rely on OMCO to produce high quality, tight tolerance customized solutions for your E-Commerce Fulfillment Center, Automated Storage and Retrieval System, or other challenging applications.

Through our Talladega, Alabama facility, OMCO Fabrication offers Contract Manufacturing Services to OEM’s across the country. Services range from regular production runs of individual components and sub-assemblies up to complete fabrication of finished equipment.

OMCO also provides Custom Fabrication work for commercial, industrial and light structural applications throughout the Southeast.

- Leading U.S. Manufacturer of Solar Trackers and Fixed Tilt Solutions

- Highest Domestic Content (Made In-House)

- 100% U.S. Produced Steel in all Roll Formed Structural Parts

- In-House Engineering Design & Support

- Factory Direct

- Exceptional Customer Support