About OMCO’s Roll Forming and Custom Roll Forming Services

Founded in 1955, OMCO is the largest custom roll former in the United States. We manufacture highly engineered shapes for many applications across a wide range of industries. Components for truck bodies, trailers, material handling systems, solar panel frames and supports, conveyors, escalators, and many more products are manufactured cost effectively using roll forming technology.

As a leader in the roll forming industry, OMCO has spearheaded many innovations, allowing us to produce the highest quality parts possible. We continuously invest in our facilities and technologies to increase our level of automation, reduce waste, and minimize changeover time.

In addition, OMCO’s extensive knowledge and experience with roll forming and related manufacturing operations provides a highly valued service to our customers. Our engineering staff can assist in redesigning a part or assembly to incorporate additional manufacturing operations, reduce assembly time, or improve durability.

Roll Forming

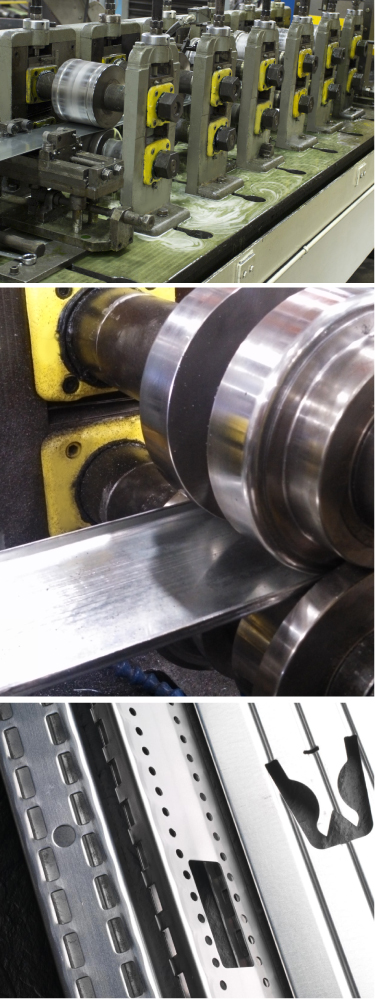

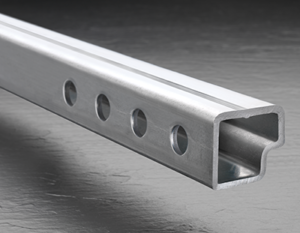

Custom roll forming is the core of our business. It is OMCO’s primary service, and it’s where our expertise lies. Custom roll forming is a highly technical process that requires years of experience to master. OMCO’s engineering staff has amassed many decades of valuable hands-on experience in roll formed part design, set design, and roll mill operation. These combined skills enable us to produce the highest quality products, on time, and at competitive prices.

Roll Forming Plus

Although roll forming is OMCO’s primary manufacturing function, most of the parts we produce require additional operations to create the final product. We refer to the combination of roll forming with additional metalworking and finishing operations as “Roll Forming Plus”. Many of these Plus operations are located right in-line with the roll forming (either prior to, nested within or right after the rolling stations). In addition, OMCO also has a long list of value added secondary manufacturing services which are performed off-line.

Custom Welded Tubes

Facilities

OMCO’s six manufacturing facilities span the United States, from Ohio to Arizona. All four locations are equipped with roll forming mills that incorporate common design parameters. Each location can perform a wide variety of supplemental metal forming operations. Together, these five factories represent over 700,000 square feet of manufacturing space and house more than 50 active roll forming mills.

Our broad geographic footprint and substantial manufacturing capacity provide the foundation that enables OMCO to deliver superior products, cost effectively, to customers throughout North America.

Locations

OMCO Corporate

30396 Lakeland Boulevard

Wickliffe, OH 44092

The OMCO corporate facility houses the executive, sales, engineering, financial and administrative departments for the OMCO group of companies. Located in Wickliffe, Ohio, it is twelve miles from downtown Cleveland.

OMCO Pierceton

1 Arnolt Drive

Pierceton, IN 46562

Our Indiana facility was constructed in 1988 and offers a full array of roll forming capabilities as well as secondary operations. It is located in Pierceton, Indiana, which is 28 miles from Fort Wayne.

OMCO Warsaw

1095 Polk Drive

Warsaw, IN 46582

OMCO Huntsville

26385 Distribution Blvd. NW, Suite 500

Huntsville, AL 35756

OMCO Solar

4550 W. Watkins St.

Phoenix, AZ 85043

OMCO established its first manufacturing operation in Arizona in 2009. This location is primarily dedicated to servicing our west coast customer base, especially those involved in the solar industry.

OMCO Southeast | Weaver & Sons

1200 Ward Avenue

Talladega, AL 35160

OMCO’s Weaver & Sons Division was acquired in 2014. It provides high quality fabrication of precision sheet and plate metal components as well as roll forming services and assembly and finishing.